Air to air heat exchangers

Air to Air Heat Exchanger Fabrication by Thompson Heat Transfer

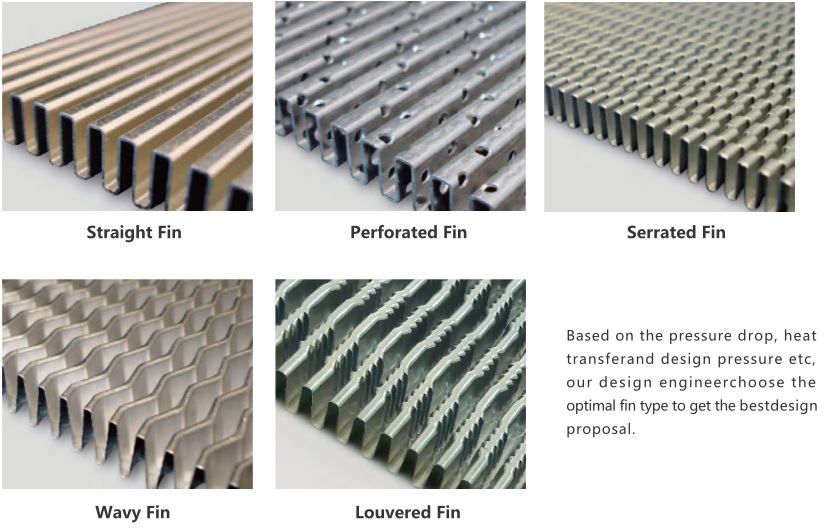

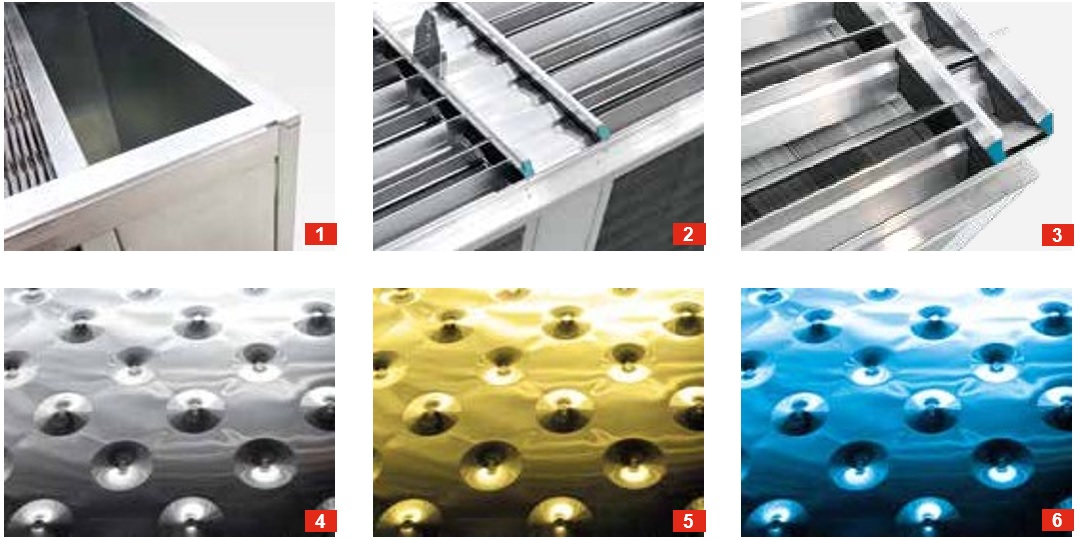

To fabricate our air to air heat exchangers, our engineers leverage a variety of in-house construction methods including folded fin fabrication, zipper fin production, nickel plating, Crom plating, heat pipe manufacturing, vacuum brazing, dip brazing, soldering, and welding. We can mix and match the best fit technologies to meet your specific application requirements.

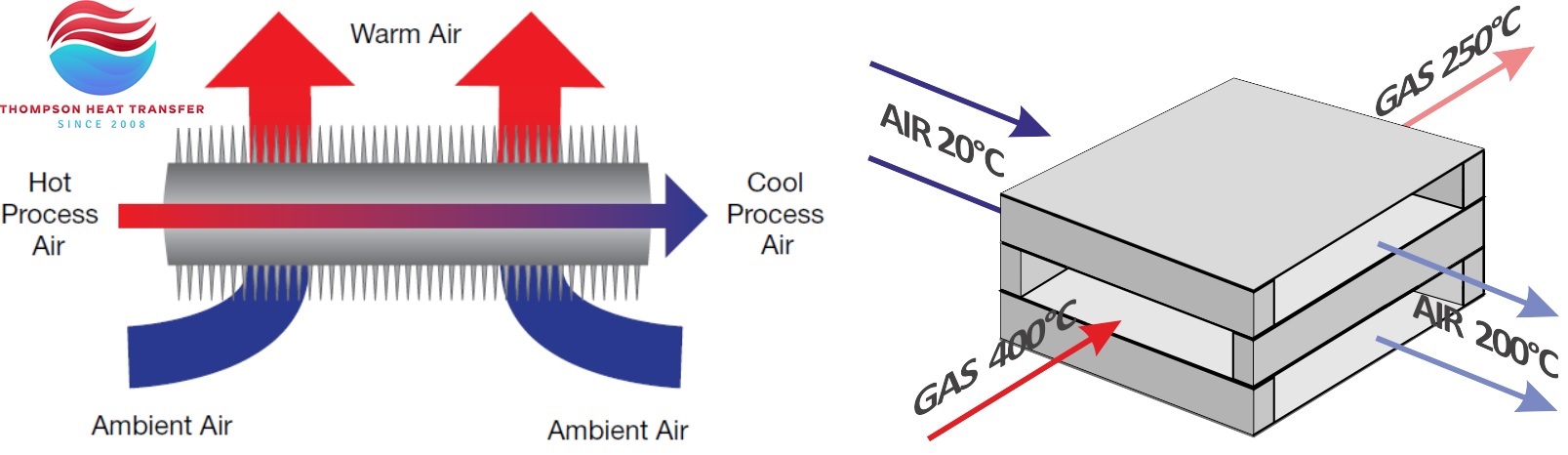

How do Air to Air Heat Exchangers Work?

Air to air heat exchangers absorb heat from the hotter air flow through a set of fins. This set of fins conducts heat into the heat exchanger. Heat is transferred from one set of fins through the heat exchanger using either conduction or passive two phase systems like heat pipes or vapor chambers. The second set of fins heat up and then conduct heat into the second air flow

Air to Air Heat Exchanger Fabrication by Thompson Heat Transfer

Effectively transfer heat from one air system to another using Boyd’s Air to Air heat exchangers. Boyd’s air to air heat exchangers leverage high conduction materials or passive two phase systems like heat pipes or thermosiphons to transport heat from one side of the heat exchanger to the other.

To fabricate our air to air heat exchangers, our engineers leverage a variety of in-house construction methods including folded fin fabrication, zipper fin production, nickel plating, Crom plating, heat pipe manufacturing, vacuum brazing, dip brazing, soldering, and welding. We can mix and match the best fit technologies to meet your specific application requirements.

Range

Airflow over 80’000 m³/h

Characteristics

- Aluminium fins, epoxy coated

- High efficiency, up to 80% fins (Gold) and hydrophilic

- Low pressure drops; suggested ∆P 200 Pa.

- Max differential pressure up to 2000 Pa (extra option up to 2500 Pa)

- Max working temperature up to 90°C (no silicone)

- Option up to 200°C

- Aluminium corner profiles and epoxy coated aluminium corner profiles. Galvanised steel, aluminium and epoxy coated galvanised steel side plates

- With or without bypass and damper

- SS304, 316 with nikel coating or crom coating

Please contact us to inspect and get suitable design.