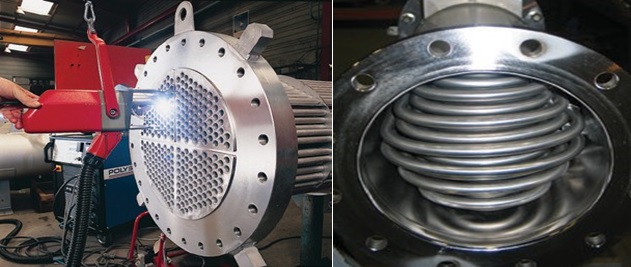

Shell and tube heat exchangers

Thompson Heat Transfer offer an extensive industrial line of heat exchangers to heating and cooling in liquid-to-vapor, vapor-to-liquid, vapor-to-vapor, liquid-to-liquid, hot oil-to-steam, among others. The shell and tube heat exchangers can be customized by customer requirments

1. According to the form of a fixed tube plate, floating head type, U-tube heat exchanger.

2. According to the structure is divided into one-way, two-pipe and multi-way tube.

3. Divided by the material of carbon steel, stainless steel and carbon steel and stainless steel mixing three condenser tubes.

4.Heat transfer area of 0.5-500 m2 can be customized

We offer an extensive industrial line of heat exchangers to achieve heating and cooling in liquid-to-vapor, vapor-to-liquid, vapor-to-vapor, liquid-to-liquid, hot oil-to-steam, hot oil-to-asphalt, and steam-to-asphalt applications, among others. Standard uses for industrial heat exchangers include regulating temperatures through HVAC systems, heating asphalt for optimal pliability, carrying out multi-stage evaporation in ethanol operations, gas cooling in landfills, and condensing organics in chemical manufacturing.

Thompson Heat Transfer industrial shell and tube heat exchangers can be customized with the following features:

- Material selection of Carbon steel, 304L & 316L stainless steel, Duplex stainless steel 2205 & 2507, Hastelloy, Alloy 20, Monel 600, AL-6XN

- Sizes up to 48” in diameter, depending on weight

- Removable tube bundles and O-rings for easy cleaning and maintenance

- U-tube or straight tube designs

- Expansion joints or floating tube sheets to aid in thermal expansion protection

- Ability to heat/cool low-fouling fluids

- ASME hydro-tested performance (includes code stamp)

- Compliance with TEMA Class C, B, or R

- Insulation jackets, free of chloride and asbestos

- Annular distributors

- Mounting supports or saddles

- Sight glasses, vacuum breakers

- Choice of ASME flanged, NPT threaded, or tri-clamp connections

- Passivation and electropolished product contact surfaces

- .......

Please contact us to inspect and get suitable design.